What exactly is the Lambda Labs QX-3 system (in engineering terms)?

The Lambda Labs QX-3 is a modular, fully horn-loaded PA architecture built from QX-3A (30° horn top) + QX-3B (kickfiller) + DH-18 “Digitalhorn” subwoofer, forming a 5-way, externally amplified and DSP-controlled system concept (sub / kick / low-mid / high-mid / HF). [0][1][2]

How does the QX-3 scale coverage, and what are the key dispersion facts?

Horizontal coverage is defined by a 30° QX-3A module and scaled by horizontal clustering of identical tops. Vertically, the QX-3A is documented with asymmetric vertical behavior (example published figure approx. +8° / −30° at −6 dB), which materially affects aiming and trim height decisions. [1][2][9][0]

What is inside a QX-3A, and how is it driven electrically?

The QX-3A is specified as a 3-way horn top with 2×12″, 32×2″ compression drivers (mid/high-mid), and 8×1″ compression drivers (HF). The connected specifications describe four amplifier channels per cabinet: two channels for the dual 12″ section plus one channel each for the 2″ array and 1″ array (with high-impedance compression sections described in the research dossier). [2][0]

What is the DH-18 “Digitalhorn” and what do its two modes do—numerically?

The DH-18 Digitalhorn is a horn-hybrid subwoofer with a mechanically reconfigurable horn path via a “Changing Lid”. Official specs state Space-Mode: 28–110 Hz (±3 dB), 102 dB 1W/1m and Directivity-Mode: 30–120 Hz (±3 dB), 104 dB 1W/1m, with D-Mode positioned for higher efficiency and built-in low-frequency pattern control. [5][6][0]

What amplification/DSP infrastructure does QX-3 assume—and what critical data is not publicly disclosed?

QX-3 is described as externally amplified and DSP-controlled (crossover, delay alignment, EQ, limiting), with presets supplied on request rather than posted as open downloads. The KW-18 is presented as the aligned touring amplifier platform (4×4500 W @ 4 Ω, all channels driven, and a 3-phase supply concept). At the same time, the connected public set does not fully disclose engineering-critical items such as complete polar datasets, explicit crossover points, and formal repeatable max-SPL figures, so the report separates documented specs from non-verified details. [0][8][7]

Method & Scope

This report is strictly grounded in the cited source set (manufacturer product pages/manuals, distributor specifications, and documented field reports). Where engineering-critical details are not publicly disclosed in that set (e.g., complete polar datasets, explicit crossover points, formal repeatable max-SPL figures), the text states “not publicly specified” instead of filling gaps with invented numbers. Any interpretation is clearly framed as interpretation—not as specification.

Download PDF

Stable reference document containing system architecture, specifications, and sourced engineering notes.

Overview

The Lambda Labs QX-3 is a modular, fully horn-loaded PA ecosystem built around three components—QX-3A (30° horn top), QX-3B (kickfiller), and the DH-18 “Digitalhorn” subwoofer—that together implement a 5-way, externally processed system aimed at high-SPL electronic music deployments. This report maps the system’s defining engineering ideas: horizontal coverage built by clustering identical 30° tops, a high-density compression-driver mid/HF topology (32×2″ + 8×1″ per QX-3A), amplitude shading for vertical energy control, and a mechanically reconfigurable sub concept where the DH-18 switches between Space-Mode (extension) and Directivity-Mode (built-in low-frequency pattern control). It also details the practical requirements the architecture implies—multi-channel amplification per top, preset-based DSP integration, alignment sensitivity, and deployment constraints—and separates what is explicitly documented from what remains unverified in publicly available data. [0][1][2]

System identity and architecture

The 5-way concept (Top + Kick + Sub)

A “QX-3 system” is not a single cabinet; it is the interaction of three modules:

- QX-3A: horn top containing low-mid, high-mid, and HF sections. [2]

- QX-3B: horn-loaded low-mid / kick extension sitting between subs and tops. [2]

- DH-18: horn-loaded subwoofer with two mechanical operating modes. [5][6]

In system terms, the frequency bands can be described as:

- Sub-bass: DH-18

- Upper bass / kick region: QX-3B

- Low-mid: QX-3A 12″ section

- High-mid: QX-3A 2″ compression-driver section

- HF: QX-3A 1″ compression-driver section

The exact crossover frequencies are not publicly specified in the connected sources; the system relies on manufacturer-supplied presets (distributed on request rather than openly posted as downloadable files). [0][8]

Horizontal clustering as the coverage strategy

The QX-3 is described as a hornloaded, horizontally clusterable array / point-source cluster system, not a line array. [0][1]

A single QX-3A is specified as a 30° horizontal module, and wider coverage is created by placing multiple modules side-by-side in a splayed cluster. [0][1][2]

This matters because it sets the “operating premise”:

- One module is intentionally narrow and is expected to be used either for long-throw/controlled coverage or as one element of a wider cluster. [1][2]

- The system’s coherence claims are inseparable from the clustering approach (how multiple 30° elements sum on-axis and in overlap zones). [1]

QX-3A Horn-Top (30° module)

Driver topology and horn integration

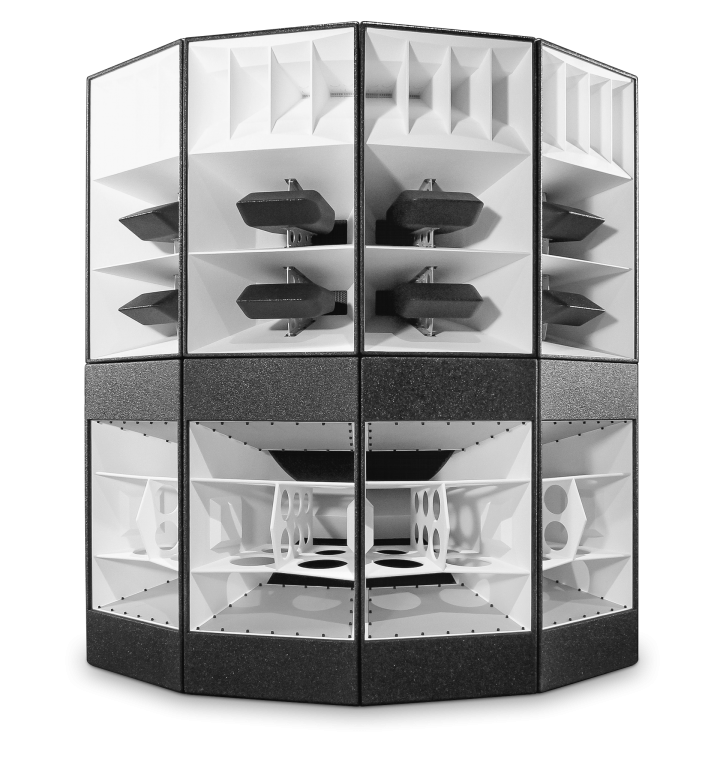

The QX-3A is an unusually dense enclosure in terms of driver count. Distributor specifications describe a 3-way horn top containing:

- 2 × 12″ horn-loaded woofers

- 32 × 2″ compression drivers (high-mid/midrange)

- 8 × 1″ compression drivers (HF)

[2]

This scale (40 compression drivers per top across two bands) is the headline engineering move: it implies high acoustic output with lower per-driver stress, which is typically advantageous for power compression and distortion at sustained high levels (general engineering principle; no single source required). The trade-off is complexity: many diaphragms, many potential failure points, and high channel count requirements.

The QX-3A is also described as a point-source enclosure (as opposed to separated mid and HF horns). [0][1]

Practically, that means the system aims to behave as a single source in the audience region—if alignment, horn geometry, and processing are executed correctly.

Amplitude shading and asymmetric vertical dispersion

Two linked ideas appear repeatedly:

- Amplitude shading as an internal pattern-shaping method. [2]

- Asymmetrical vertical dispersion, with more energy aimed downward relative to the cabinet axis. [1][9]

A manufacturer social post provides a numeric description of the vertical behavior for a single QX-3A: approximately +8° / –30° (–6 dB) relative to axis (and additional –9 dB points are referenced in the research dossier). [0][9]

That asymmetry is not a cosmetic spec; it changes how a system tech can aim and trim the cluster. The implied intent is typical of venue-sound optimization: keep useful energy on listeners while reducing ceiling/upper-wall spill. [9]

Amplifier channels, impedance structure, and wiring implications

The QX-3A is a fully active loudspeaker requiring multiple amplifier channels. In the connected specifications, the top is described as needing four amplifier channels per cabinet:

- one channel per 12″ woofer (two channels total for the 12″ section),

- one channel for the 32×2″ section,

- one channel for the 8×1″ section.

[0][2]

Distributor spec data also indicates an unusual electrical picture for the compression-driver sections: the combined 2″ and 1″ sections are described as high-impedance aggregates (values in the research dossier cite ~64 Ω totals for each compression section). [0][2]

That architecture is consistent with many drivers being series/parallel combined to form a manageable load while sharing power across many diaphragms.

Connectivity is described as NL8-based for the top cabinet (with in/out). [0][2]

Important engineering note: exact NL8 pin mapping is not publicly confirmed in the connected sources; any pinout details beyond “NL8 is used to carry multiple ways” should be treated as implementation-specific unless provided in official wiring documentation. [0]

QX-3B Kickfiller Module

Purpose: the “kick” band and headroom management

The QX-3B is specified as a horn-loaded module with:

- 2 × 15″ drivers (4″ voice coils)

- 4 Ω nominal impedance

- ~76 kg weight

- ~4.5 kW amplifier power recommendation

[2]

Its role is described as low-mid extension / kick reinforcement between sub and top. [0][2]

A precise frequency response for the QX-3B is not published in the connected official sources; any numeric range commonly associated with “kick” coverage should be treated as an engineering estimate, not a manufacturer spec. [0]

In system terms, the kickfiller function is about headroom partitioning: taking the upper bass load off the top and shaping the subjective “impact band” that often defines perceived punch in electronic music playback.

Electrical/physical integration with QX-3A

The QX-3B is described as being integrated into the stack/cluster mechanically (matched footprint concepts are referenced) and can be powered via standard speaker connectors (NL4 usage is referenced in the research dossier). [0][2][10]

The system-engineering consequence is straightforward:

- a QX-3A cluster is already multi-channel,

- adding QX-3B increases output channels and processing complexity,

- alignment between DH-18 ↔ QX-3B ↔ QX-3A becomes one of the most critical tuning steps (delay + crossover phase management). [0]

DH-18 “Digitalhorn” Subwoofer

Segmented horn concept

The DH-18 is presented as a horn-hybrid subwoofer using a segmented (stepped) horn expansion (the “digital horn” concept). [5]

In addition to the geometry concept, the DH-18 is notable because it implements two operating modes via mechanical reconfiguration rather than requiring an external cardioid stack and dedicated cardioid DSP.

Space-Mode vs Directivity-Mode (mechanical reconfiguration)

Official DH-18 material describes:

- Space-Mode (S-Mode): 28–110 Hz (±3 dB)

- Directivity-Mode (D-Mode): 30–120 Hz (±3 dB)

- Sensitivity: 102 dB (S-Mode) / 104 dB (D-Mode), 1W/1m

[5]

Switching modes is done by repositioning a “Changing Lid” panel, described in the DH-18 manual. [6]

Directionality without external cardioid arrays

The DH-18’s D-Mode is described as providing inherent forward directivity (with rear attenuation referenced in the research dossier). [0][5]

The dossier also reports a deployment pattern where two stacked DH-18 in D-Mode form a wide-cardioid behavior at very low frequencies (rear rejection referenced around 30 Hz). [0]

From an engineering standpoint, the value proposition is clear: achieving meaningful rear attenuation in the sub band typically costs array length, additional cabinets, and careful delay/phase programming. A mechanically reconfigurable directivity mode is a distinctive system-design choice—especially for event contexts where array depth and setup time are constrained.

Dispersion, arraying, and coverage planning

30° per module, building wider coverage by clustering

A single QX-3A is a 30° horizontal module. [1][2]

The system’s intended horizontal coverage planning is essentially:

- determine required audience horizontal span,

- divide by 30°,

- cluster that many QX-3A modules per side (with appropriate splay geometry and trim height).

The QX-3 product page and connected material also reference the concept of broad clustering capability (including 360° concepts in principle). [0][1]

Vertical behavior: why asymmetry changes aiming and trim

The approximate +8° / –30° vertical behavior means the “useful vertical window” is not centered on the cabinet axis. [9]

In practical deployment terms, that tends to reduce the need for vertical stacking of tops (the system is primarily designed for horizontal clustering), while emphasizing careful cluster tilt and trim height so the down-tilted energy lands where intended.

Processing and amplification ecosystem

Active multi-way requirement (no internal amplification/DSP)

None of the QX-3 modules are described as self-powered; the system is built to be used with external amplification and DSP. [0][2]

The connected sources also state that presets are supplied to customers on request and are not broadly posted as public downloads. [0][8]

From a channel-count standpoint, a minimal per-side output structure looks like:

- Sub band (DH-18)

- Kick band (QX-3B)

- Low-mid (QX-3A 12″ section; two channels per top)

- High-mid (QX-3A 2″ section)

- HF (QX-3A 1″ section)

The number of DSP outputs rises quickly with cluster size because the QX-3A itself is multi-amplified. [0][2]

KW-18 amplifier design intent and power realities

Lambda Labs presents the KW-18 (Kraftwerk 18) as an in-house touring amplifier aligned with the power demands of the QX ecosystem. [7]

The KW-18 is described as a 4-channel Class-D amplifier with:

- 4 × 4500 W @ 4 Ω (all channels driven)

- 4 × 2300 W @ 8 Ω (all channels driven)

- and a 3-phase supply concept targeting high continuous output. [7]

The KW-18 page also highlights design aims such as very high damping factor and low distortion (“reference” intent). [7]

Early adopters are also described as using high-end touring platforms with integrated DSP (e.g., Lab.Gruppen PLM + Lake), indicating that the system can be driven successfully with non-Lambda infrastructure if processing and power are adequate. [0][2]

Presets, availability, and integration workflow

Lambda Labs’ support/downloads area is referenced as not containing broadly posted QX-3 preset files, implying distribution by request. [8]

That shapes the integration workflow:

- Obtain factory target processing (crossover, EQ, limiting, delay)

- Implement in a capable DSP platform

- Validate alignment on site (measurement microphone + transfer function / impulse response)

- Set protection (especially for compression-driver sections)

- Adjust for venue acoustics and audience absorption

The most critical technical point is delay/phase alignment between horns: horn path length differences can be large, and the subjective “punch” of the system depends strongly on coherence through the kick/low-mid transitions. [0]

Performance implications

Why “many small drivers” can stay clean at high output

The QX-3A’s compression-driver count is extraordinary. [2]

From an engineering standpoint (general principle), distributing acoustic work across many diaphragms typically reduces:

- per-driver excursion and heating,

- power compression at sustained SPL,

- distortion from overdriving single elements.

That said, the performance outcome depends on manifold/horn design, phase plugs/path length control, and processing—all areas where the connected public sources do not provide full technical disclosure (for example: detailed polar plots and measured beamwidth vs frequency are not publicly available in the connected set). [0]

Coherence goals: what can be stated, what remains inference

The QX-3 product material uses language indicating a strong focus on coherent horizontal clustering (including terms such as “phase weighting” and coherence claims). [1]

Without detailed public polar data and crossover information, the mechanism by which this is achieved across frequency remains partly interpretive. The safe engineering reading is:

- coherence is an explicit design goal,

- the system’s geometry and processing are designed to support multi-cabinet horizontal clusters,

- the degree of coherence realized in practice depends on splay accuracy, aiming, alignment, and venue acoustics.

[0][1]

Deployment patterns observed in the field

Club/festival patterns

Case study and field references indicate QX-3 deployments in club and event contexts, including documented Austrian coverage and deployment write-ups (e.g., Pro Performance features). [3][4]

Social posts also show clustered point-source arrays and large subwoofer inventories in event contexts. [12]

Community threads discuss where systems have been encountered and provide anecdotal listening impressions—useful as qualitative context, not as a substitute for measurement. [13][14]

Rigging approach for clustered point sources

The QX-3A is designed to be clustered horizontally rather than flown as a long vertical line. [1]

A manufacturer video demonstrates fast rigging of a clustered system concept. [11]

An installation post references a “60 degree setup” in an installed context, consistent with a multi-module cluster concept. [10]

Rigging hardware specifics (safe working loads, frame part numbers, etc.) are not captured in the connected public sources; those details typically live in manufacturer rigging manuals or direct integrator documentation. [0]

Known unknowns and engineering risks

Missing public data

Several important engineering details are not publicly disclosed in the connected sources set:

- Exact crossover points between the QX-3A internal ways and between modules (sub/kick/top). [0]

- Full polar data / beamwidth vs frequency for the QX-3A and QX-3B. [0]

- Max SPL specifications as formal, repeatable datasheet values for the full system components. [0]

- Driver make/model details for compression drivers and OEM/custom elements. [0]

These gaps do not prevent competent deployment, but they increase reliance on factory presets, measurement-driven alignment, and experienced system technicians.

Practical risks: complexity, channel count, serviceability

Even without discussing pricing, the QX-3 presents practical engineering “costs” in a non-financial sense:

- High amplifier channel count per top cabinet. [2]

- High DSP output requirements for stereo systems with multiple tops per side. [0]

- Service complexity due to the number of compression drivers in the QX-3A. [0]

- Power infrastructure considerations (KW-18 is designed around high continuous output and multi-phase operation). [7]

The system’s strengths—controlled coverage, horn efficiency, and high headroom—are tightly linked to these demands. In other words: it is not “plug-and-play”; it is “build-and-align.”

Conclusions

The Lambda Labs QX-3 is best understood as a system architecture rather than a single loudspeaker model: a narrow 30° horn top (QX-3A) designed for horizontal clustering, supported by a dedicated kick module (QX-3B) and a mechanically dual-mode subwoofer (DH-18). [0][1][2][5][6]

Technically, the design signals an uncompromising set of priorities: horn loading across the entire spectrum, tight horizontal control, and a component ecosystem (processing + amplification) sized for sustained high output. [1][7]

Where the public dataset is strongest is in module identity, topology, and the DH-18’s mode behavior. Where it is weakest is in the details that often matter most for predictive engineering: full polars, explicit crossover points, and formal max SPL data. [0]

For the electronic music community, the QX-3’s appeal is consistent with what the architecture suggests: if deployed and aligned correctly, it is built to deliver extremely high output with controlled dispersion and a system-wide horn character that prioritizes impact and clarity under load. [0][1][3][4]

6)

Key takeaways

- QX-3 is a system family: QX-3A (top) + QX-3B (kick) + DH-18 (sub), forming a 5-way architecture. [0][2]

- The QX-3A is a 30° horizontal module intended for horizontal clustering to build wider coverage. [1][2]

- QX-3A driver topology is extreme: 2×12″ + 32×2″ + 8×1″ in one horn top. [2]

- Vertical behavior is asymmetric (approx. +8°/–30° at –6 dB), affecting aiming and trim decisions. [9]

- QX-3A is multi-amplified (four amplifier channels per cabinet in the connected specs). [0][2]

- DH-18 provides two official modes via mechanical reconfiguration: S-Mode 28–110 Hz and D-Mode 30–120 Hz with higher sensitivity in D-Mode. [5][6]

- The KW-18 is positioned as the in-house amp solution: 4×4500 W @ 4 Ω (all channels driven) with a multi-phase design intent. [7]

- Key public unknowns remain: detailed crossovers, full polar data, formal max SPL figures, and driver make/model disclosure. [0]

Sources

[0] Executive Summary — “Lambda Labs QX-3 – Deep Technical Research Summary.pdf”

[1] Lambda Labs — “QX-3” product page:

https://lambda-labs.com/en/products/qx-3

[2] DCS SoundSystem — “QX3 | DCS - Lambda Labs” (QX-3A/QX-3B specs):

http://www.dcs-soundsystem.be/en/products/qx-series/qx3

[3] Pro Performance — “The Lambda Labs QX series”:

https://www.properformance.audio/articles/the-lambda-labs-qx-series

[4] Pro Performance — “Sound Stories: PRST”:

https://www.properformance.audio/articles/sound-stories-prst

[5] Lambda Labs — “DH-18 Digitalhorn” product page:

https://lambda-labs.com/en/products/dh-18

[6] Lambda Labs — “DH-18 Manual” (PDF):

https://lambda-labs.com/user/pages/03.products/03.subwoofers/03.dh-18/_downloads/DH-18_manual.pdf

[7] Lambda Labs — “KW-18” product page:

https://lambda-labs.com/en/products/kw-18

[8] Lambda Labs — Support/Downloads page:

https://lambda-labs.com/en/support/downloads

[9] Lambda Labs (Facebook) — asymmetrical vertical coverage post:

https://www.facebook.com/lambdalabsaustria/posts/steer-the-sound-to-your-listeners-and-not-elsewhereqx-3s-asymmetrical-vertical-c/2742684602436261/

[10] Lambda Labs (Facebook) — “QX-3 installation … Dresden (60 degree setup)” post:

https://www.facebook.com/lambdalabsaustria/posts/qx-3-installation-objekt-klein-a-in-dresden-qx-3-60-degree-setup-with-qx-b-kickf/1670231086348290/

[11] Lambda Labs (Facebook video) — rigging example:

https://www.facebook.com/lambdalabsaustria/videos/an-example-how-to-rig-the-qx-3-soundsystem-in-a-few-minutes/697584838200001/

[12] Lambda Labs (Facebook) — Draaimolen cluster post:

https://www.facebook.com/lambdalabsaustria/posts/draaimolen-netherlands-today-2-x-120-degree-point-source-cluster-qx-3-and-24-x-d/1560629453975121/

[13] Reddit — r/SoundSystem thread (“Is there a single Lamba qx3 system in the US?”):

https://www.reddit.com/r/SoundSystem/comments/1g9qx4s/is_there_a_single_lamba_qx3_system_in_the_us/

[14] Reddit — r/audiophile thread (QX-3 impressions):

https://www.reddit.com/r/audiophile/comments/12pvwrd/lambda_labs_qx3_anyone_stood_infront_of_those/

[15] YouTube — TONLADEN “Atlas Festival 2018 with Lambda Labs QX-3”:

https://www.youtube.com/watch?v=Eoa3Uz9qKoE

[16] Speakerplans forum — “Hornloaded System” thread (page 6):

https://forum.speakerplans.com/hornloaded-system_topic96230_page6.html